|

| Dave carries a large stock off free pair skinny magnet, 2.5mm thick front O ring, 1.0mm thick rear O ring and one pair "just in case" rear axle plastic spacers as per Ecurie rule 3.3 - just ask and you will receive these. There are other Ecurie experienced who will have similar. My own current source: Strong-Rare-Earth-Bar-Neodymium-Magnets-N50-25x5x1-5mm O ring 2.5mm thick by 17mm or 18mm OD |

01 December 2016

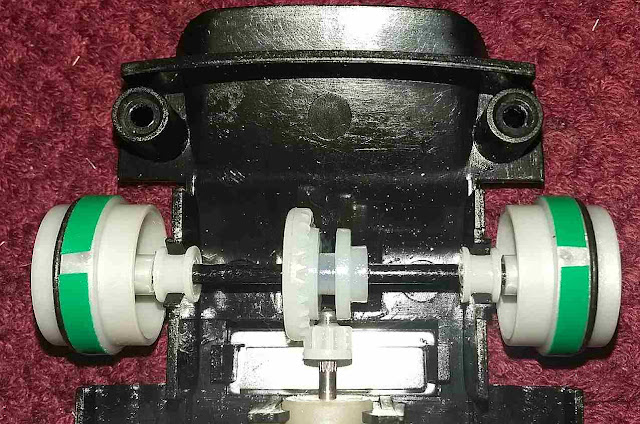

Costa concept stock inline car race preparation 2016

Subscribe to:

Posts (Atom)