The excellent Professor controllers have been an Ecurie go to for some years and personal preference has swung to the dual transistor plus heatsink versions, now available from Raceworld in Cape town in fixed sensitivity and brake version:

This guide is for fitting the stage one to stage three adjustment controls - Professor does strongly recommend (no I don't know why not the earlier compact version) this 25 ohm sensitivity potentiometer for these controllers despite the fiddly fit requiring short wires, so I ordered accordingly:

Per Professor: "This pot is used ONLY on the newer version circuit boards that are fitted with or have the capability to have dual transistors installed - That includes controller model numbers PMTR2104, PMTR2106 and PMTR2130 AND may also be used at times in other models."

This the Professor version brake potentiometer, although one can leave the wire bridge in and externalise with pretty much any after market 5 watt 25 ohm (ish) wirewound potentiometer as I have done on top of the three pin plug in pics below, simply splice in to the "red" brake lead (nicely marked by Raceworld) and leave the brake bridge intact:

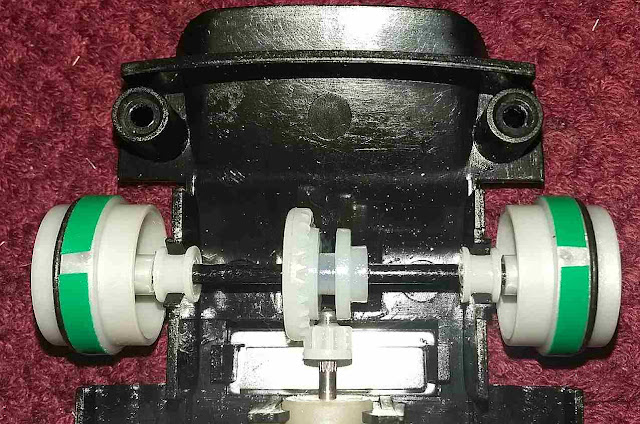

Stage 1: Fine for clubbie magnet racing and 1/24 production, the bridges shown in the bottom pic, un-solder for which ever potentiometers you are fitting, that is all that is necessary for this level of racing:

The stage 2 fixed sensitivity average resistor of 8 ohms only needs to be switched for a 4 ohm (between 2 ohm and 5 ohms is fine) if you intend doing 1/32 plastic non magnet racing ala the Slot.it South Africa series and require a softer bottom end sensitivity - very likely voids warranty.

The resistor cut is to splice in the stage 3 Cranmer Curve 50 ohm preset if you considering doing plastic non magnet racing only - very likely voids warranty.

The pic below illustrates the fiddly fit for the recommended Professor Sensitivity potentiometer - shorten the solder tabs right down and it will fit with a push and turn to locate as shown:

The stage 2 and stage 3 tweaks can be ignored for most clubbie magnet and 1/24 racing, the pics below show the location of the 50 ohm Cranmer Curve pot super glued in and accessible through the controller top. A quick test on the home brew tester and the controller working sweet:

This very crude (but surprisingly effective) Cranmer Curve preset emulates the variable resistance boards used in top end transistor controllers, by changing the final "step" in the resistor chain. Sir Lancelot himself indeed finding it useful in other classes as well.

There we go, a controller for all my racing needs from 1/32 plastic Slot.it non magnet series right through magnet and on to Falcon and S16D type 1/24 metal racing, as we will encounter at Raceworld.